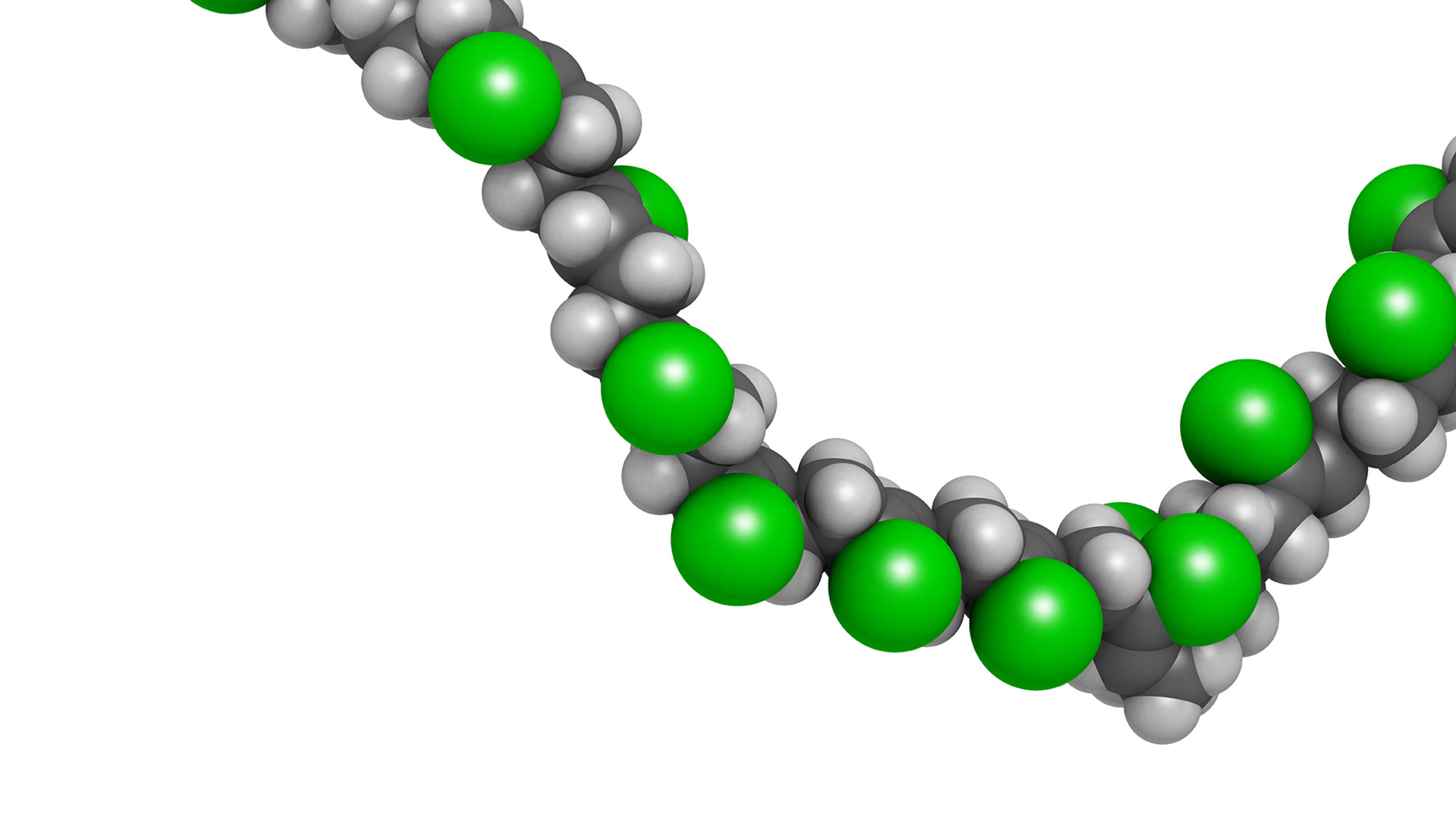

About CR chlorobutadiene

Neoprene rubbers are homopolymers of chloroprene (chlorobutadiene) and were among the earliest synthetic rubbers used to produce seals. CR has good aging characteristics in ozone and weather environments, along with abrasion and flex cracking resistance.

CR is not effective in aromatic and oxygenated solvent environments. Neoprene can be compounded for service temperatures of -40°C to + 110°C (-40°F to +230°F).Most elastomers are either resistant to deterioration from exposure to petroleum based lubricants or oxygen. Neoprene is unusual in having limited resistance to both.

CR applications

This, combined with a broad temperature range and moderate cost, accounts for its desirability in many sealing applications for refrigerants like Freon® and ammonia. CR is resistant to refrigerants, ammonia, Freon® ( R12, R13, R21, R22, R113, R114, R115, R134A), silicone oils, water, ozone, vegetable oils, alcohols, and low-pressure oxygen. CR has a very low resistance to mineral oils.

Datasheets CR

The table below shows the available datasheets for this material in pdf. Safety datasheets are available here.

Plus d'information concernant des joint toriques CR d'ERIKS

Si vous avez des questions concernant ERIKS Sealing & Polymer, remplir le formulaire ci-dessous ou contacter la location d'ERIKS Sealing & Polymer le plus proche.

| Compound number | Material | Nominal hardness | Compliances | Application | Colour | Minimum temperature | Maximum temperature | Datasheet |

|---|---|---|---|---|---|---|---|---|

| 32906 | CR | REACH,RoHS | Chemical Processing | General purpose | Black | -35.0 | 110.0 |