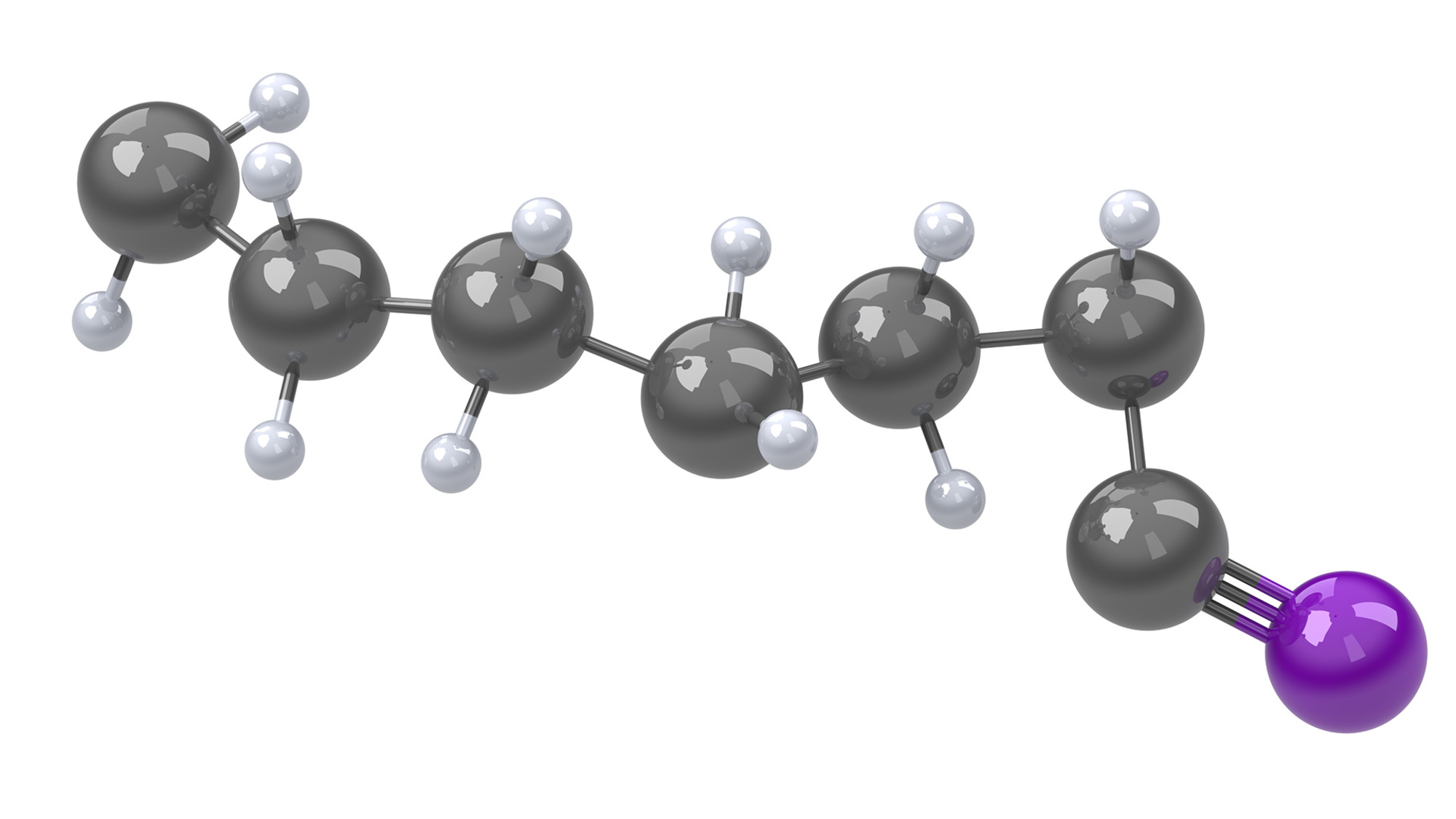

About HNBR

HNBR has been developed to meet higher temperatures than standard NBR while retaining resistance to petroleum based oils. Obtained by hydrogenating the nitrile copolymer, HNBR fills the gap left between NBR, EPDM and FKM elastomers where high temperature conditions require high tensile strength while maintaining excellent resistance to motor oils, sour gas, amine/oil mixtures, oxidized fuels, and lubricating oils.

HNBR applications

HNBR is resistant to mineral oil-based hydraulic fluids, animal and vegetable fats, diesel fuel, ozone, sour gas, dilute acids and bases. HNBR also resists new bio-oils (biological oils). HNBR is suitable for high dynamic loads and has a good abrasion resistance. HNBR is suitable for temperatures from -30°C to +150°C (-20°F to +302°F).

The carboxyl group is added to significantly improve the abrasion resistance of NBR while retaining excellent oil and solvent resistance. XNBR compounds provide high tensile strength and good physical properties at high temperatures. XNBR is suitable for temperatures from -30°C to +150°C (-20°F to +302°F).

Datasheets HNBR

The table below shows the available datasheets for this material in pdf. Safety datasheets are available here.

More information about HNBR at ERIKS

For more information on HNBR or one of our other o-ring materials please contact one of the ERIKS Sealing & Polymer locations, or fill in the form below.

| Compound number | Material | Nominal hardness | Compliances | Application | Colour | Minimum temperature | Maximum temperature | Datasheet |

|---|---|---|---|---|---|---|---|---|

| 88625 | HNBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 150.0 | ||

| 886172 | HNBR | 3-A,FDA 21 CFR 177-2600,EC1935-2004,ADI,REACH,RoHS | Food and Beverage | Black | -40.0 | 150.0 | ||

| 886270 | HNBR | FDA 21 CFR 177-2600,EC1935-2004,ADI,REACH,RoHS | Food and Beverage | Yellow | -30.0 | 150.0 | ||

| 88629 | HNBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 150.0 |