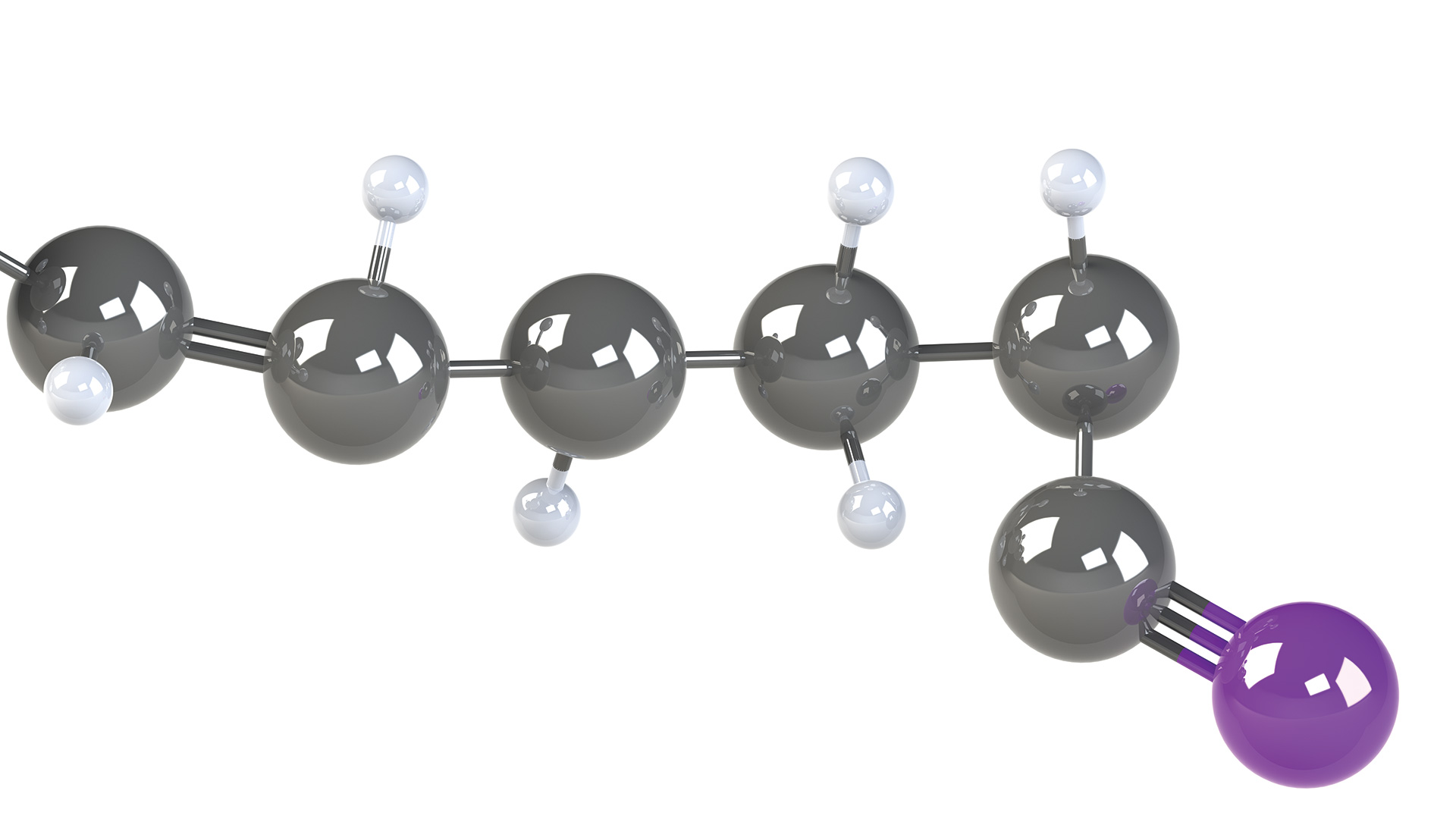

NBR Nitrile

NBR (Nitrile), chemically, is a copolymer of butadiene and acrylonitrile. Acrylonitrile content varies in commercial products from 18% to 50%. As the NBR content increases, resistance to petroleum base oils and hydrocarbon fuels increases, but low temperature flexibility decreases.

About NBR

Due to its excellent resistance to petroleum products, and its ability to be compounded for service over a temperature range of -35°C to +120°C (-30°F to +250°F), Nitrile /NBR is the most widely used elastomer in the seal industry today. Also many military rubber specifications for fuel and oil resistant O-rings require nitrile based compounds.

It should be mentioned that to obtain good resistance to low temperature, it is often necessary to sacrifice some high temperature resistance. Nitrile compounds are superior to most elastomers with regard to compression set, tear, and abrasion resistance. Nitrile compounds do not possess good resistance to ozone, sunlight, or weather. They should not be stored near electric motors or other ozone generating equipment.

NBR applications

NBR parts should be kept from direct sunlight. However, this can be improved through compounding. NBR is the standard material for hydraulics and pneumatics. NBR resists oil-based hydraulic fluids, fats, animal and vegetable oils, flame retardant liquids (HFA, HFB, HFC), grease, water, and air. Special low-temperature compounds are available for mineral oil-based fluids. By hydrogenation, carboxylic acid addition, or PVC blending, the nitrile polymer can meet a more specified range of physical or chemical requirements. The quality of Nitrile-compounds depends on the percentage of acrylonitrile in the base polymer.

Datasheets NBR

The table below shows the available datasheets for this material in pdf. Safety datasheets are available here.

Ask ERIKS

For more information on Nitrile / NBR or one of our other o-ring materials please contact one of the ERIKS Sealing & Polymer locations or fill in the form below.

| Compound number | Material | Nominal hardness | Compliances | Application | Colour | Minimum temperature | Maximum temperature | Datasheet |

|---|---|---|---|---|---|---|---|---|

| 36624 | NBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 120.0 | ||

| 44501 | NBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 120.0 | ||

| 44601 | NBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 120.0 | ||

| 47702 | NBR | ADI,REACH,RoHS | General purpose | Black | -30.0 | 120.0 | ||

| 366202 | NBR | EN549 B2 H2,ADI,REACH,RoHS | Gas distribution | Black | -30.0 | 120.0 | ||

| 366221 | NBR | EN682 GBL,ADI,REACH,RoHS | Gas distribution | Black | -30.0 | 120.0 | ||

| 366300 | NBR | EN549 B2 H3,ADI,REACH,RoHS | Gas distribution | Black | -30.0 | 120.0 | ||

| 366470 | NBR | 3-A,FDA 21 CFR 177-2600,EC1935-2004,ADI,REACH,RoHS | Food and Beverage | Black | -30.0 | 110.0 | ||

| 366472 | NBR | FDA 21 CFR 177-2600,ADI,REACH,RoHS | Food and Beverage | White | -25.0 | 110.0 | ||

| 366540 | NBR | NSF61,WRAS,ADI,REACH,RoHS | Drinking water | Black | -30.0 | 120.0 |