Reduce your time to market

ERIKS’ Application Engineers are often involved in product design and development. R&D departments and specialized companies in the manufacturing industry involve ERIKS at an early stage in the development process for engineering, research, design and maintenance.

A tangible 3D prototype in less than no-time

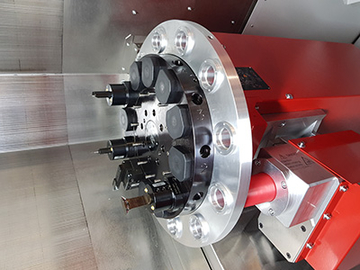

With our Rapid Prototyping facilities, we can save you R&D time by developing elastomeric/polymeric parts. Is it urgent or do you require a small quantity of seals or custom molded parts? No problem for ERIKS.

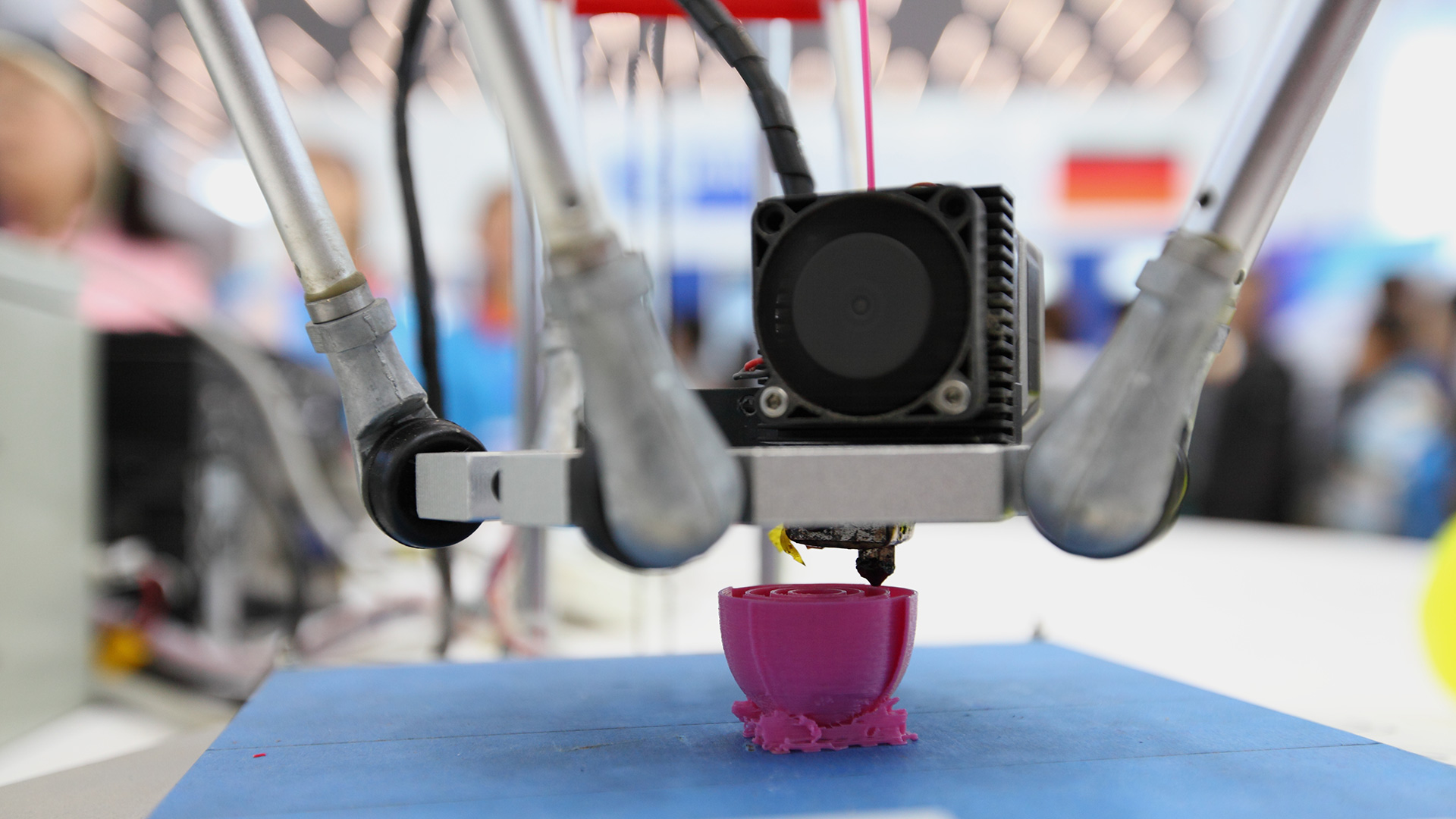

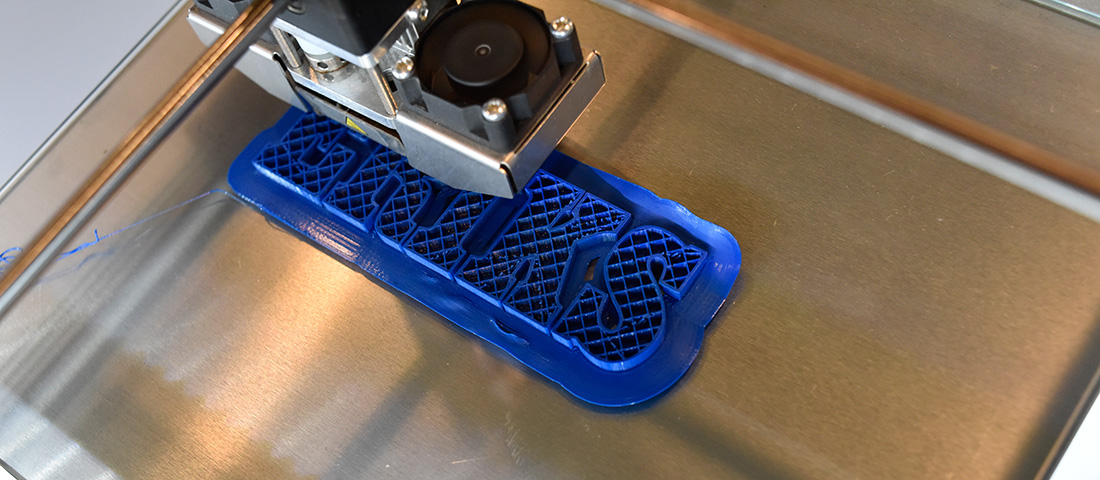

3D printing

ERIKS can print 3D in many rubber like materials, silicone and plastics. A mix of materials in specific concentrations and structures is also possible. This equals the mechanical properties and appearance of your end product.

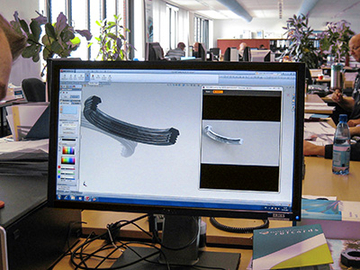

Using computer animation tools like SolidWorks and the latest 3D CAD technology, you can convert your ideas, concepts or innovations into tangible prototypes within a few days. This will help you to speed up your development process.

You can fully analyze and test these samples and prototypes and it is immediately clear whether the design is correct or needs further development. It can even inspire you to develop new ideas!

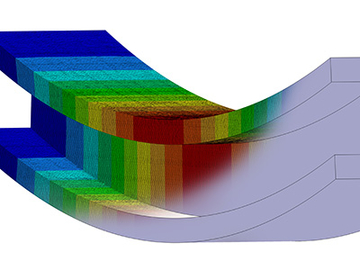

ERIKS offers you the best support | Speed up the product development process with Finite Element Analysis (FEA) | Prototyping and 0-series with the SealXpress |

|  |  |

| By incorporating simulations we can speed up the product development process and minimize costs. ERIKS offers simulations based on Finite Element Analyses in which the concepts are digitally exposed to the full range of external physical stresses, upon which conclusions can be drawn. |

|

Contact us about Rapid Prototyping

If you have any questions about Rapid Prototyping and other sealing solutions, please contact one of our locations or fill in the contact form below.